In this chapter, we talk about x-ray generator and their different types with their safety measures.

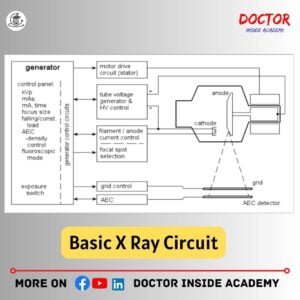

Basic X-Ray Circuit

X ray circuit is a connection between different x-ray components in the x-ray tube.

The ray circuit’s primary function is to generate and control X-rays, which are crucial for capturing internal images of the human body, and at the heart of the X-ray circuit is the X-ray tube.

The X-ray tube is a specialized vacuum-sealed enclosure containing a cathode and an anode. When the circuit is activated, a high voltage is applied across the X-ray tube.

The cathode emits a focused stream of electrons, which are accelerated towards the anode, resulting in the Production of X-Rays.

To provide the necessary high voltage for electron acceleration, a high-voltage generator is employed in the X-ray circuit. This generator typically includes a step-up transformer that increases the voltage from the power source to the level required by the X-ray tube.

Main Components of a Basic X-Ray Circuit

The main components of x ray tube are followings:

X-ray Tube

The X-ray tube is the primary component responsible for generating X-rays. It is made up of an anode and a cathode.

When high voltage is applied across the cathode and anode, electrons are emitted and accelerated towards the anode. The sudden deceleration of these electrons at the anode produces X-rays.

High-Voltage Generator

The high-voltage generator is used to supply the high voltage required for X-ray production. It typically consists of a high-voltage transformer that steps up the input voltage to the required levels and a high-voltage generator that converts the stepped-up voltage into a direct current (DC) high voltage.

Control Console

The control console is the user interface for operating the X-ray system. It typically includes various controls such as exposure time, X-ray tube current, and voltage.

The operator can adjust these parameters based on the specific imaging requirements.

Filament Circuit

The filament circuit is responsible for heating the cathode filament inside the X-ray tube. The filament is made of a material that emits electrons when heated. By passing a current through the filament, it heats up and emits electrons that will be accelerated toward the anode when the X-ray exposure is initiated.

Exposure Switch

The exposure switch is a foot pedal or hand switch that controls the timing of the X-ray exposure. When the switch is pressed, the high voltage is applied to the X-ray tube, and X-rays are generated. Releasing the switch stops the X-ray production.

X-ray Collimator

The X-ray collimator is a device located near the output of the X-ray tube that helps shape and limit the X-ray beam. It consists of lead shutters or adjustable blades that can be used to restrict the size and shape of the X-ray field, reducing unnecessary radiation exposure to the patient.

X-ray Image Receptor

The X-ray image receptor captures the X-rays that pass through the patient’s body and forms the final X-ray image. There are two main types of image receptors: film-based (analog) and digital detectors. Film-based receptors use X-ray film that needs to be developed, while digital detectors capture the X-rays electronically and provide instant digital images.

These are the basic components of an X-ray circuit. However, it’s important to note that modern X-ray systems can have additional components and features for improved functionality, such as automatic exposure control, digital image processing, and radiation dose monitoring systems.

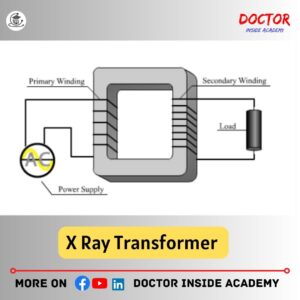

X Ray Transformer

In an X-ray circuit, a transformer is an essential component used to step up the voltage supplied to the X-ray tube. The transformer plays a crucial role in increasing the voltage to the levels necessary for X-ray production.

The transformer in an X-ray circuit is typically a step-up transformer, which means it increases the input voltage to a higher output voltage. It consists of two sets of coils wound around a core, known as the primary and secondary windings.

X Ray Transformer has two Coils

There are two types of coils in x ray transformers: primary coil and secondary coil.

Primary Coil

The primary coil is the primary winding and is connected to the power supply and receives the input voltage.

The electromagnetic induction theory underlies how the transformer functions.

When alternating current (AC) flows through the primary winding, it creates a varying magnetic field around the core. According to Faraday’s law of electromagnetic induction, the secondary winding induces a voltage in response to the changing magnetic field.

Secondary Coil

The secondary coil in a transformer is the coil of wire that is responsible for receiving the induced voltage from the primary coil and providing the stepped-up or stepped-down voltage at the output of the transformer.

The secondary coil has a different number of turns compared to the primary coil, which determines the voltage transformation ratio of the transformer. If the secondary coil has more turns than the primary coil, it is called a step-up transformer, and it increases the input voltage.

Conversely, if the secondary coil has fewer turns than the primary coil, it is called a step-down transformer, and it decreases the input voltage.

The secondary coil is connected to the X-ray tube, providing the stepped-up voltage necessary for X-ray production.

So, these are the basics of the primary coil and secondary coil, we covered.

X Ray Generator

X ray generator is a device, that supplies power to the x ray tube.

X Ray Generator consists of several key components that work together to generate and control the production of X-rays.

X Ray Tube requires Electrical Energy for Two Main Purposes;

- For thermionic emission at the cathode,

- To accelerate electrons from cathode to anode.

Main Components of an X-ray Generator

- High-Voltage Generator,

- X-ray Tube,

- Filament Circuit,

- Control Console,

- Exposure Switch,

- X-ray Collimator,

- X-ray Control Unit.

These are the main components of x ray generator and the next section describes these components in detail.

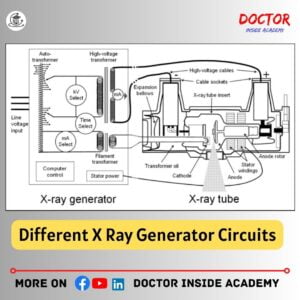

Different X Ray Generator Circuits

X ray circuit is an interconnection between electrical elements in the x-ray tube called the x-ray circuit.

There are 3 main types of x ray generator circuits, are followings;

High Voltage Circuit

High voltage circuit is responsible for generating and supplying the high voltage required to accelerate electrons in the X-ray tube, leading to the production of X-rays.

High Voltage Circuits create the x rays by modifying the power from the source.

Filament Circuit

The filament circuit ensures the filament has the most suitable thermionically emitted electron cloud by using the incoming power.

The Filament Circuit is controlled by the MA selector.

Higher the MA, higher the current, higher the thermionic emission, and the stronger electron cloud formation.

Timer Circuit

The timer circuit simply memes controls the duration of exposure.

The main circuit and filament circuit are combined to form the complete basic X-ray circuit that is composed of a sequence of devices to produce x-rays.

Different Types of X Ray Generators

X ray generators are also classified into 3 main types based on their phases in those generators.

Single Phase Generator

Based on the kind of input electricity it gets, the single-phase generator operates.

The single-phase generator receives an AC (Alternating Current) from a single-phase source, unlike other X-ray generators, including the three-phase generators. The primary and secondary portions of the circuit, also referred to as the low-voltage and high-voltage parts, respectively, are made up of two parts.

The primary side essentially consists of the autotransformer, line voltage kilovolt selector, compensator, focal spot selection, kilovolt meter, filament transformer, exposure switch, and other particular components.

Three Phase Generator

Three phase x-ray generator is also based on its input power which is a three-phase AC (Alternating Current) input which typically are three separate supply lines from the power grid.

While the amplitude and frequency of these independent input lines are identical, their phases change significantly when it comes to the waveforms of the AC current.

The first, second, and third input lines, respectively, have a phase difference of 0, 120, and 360 degrees between them. The voltage variation at the output end is frequently significantly reduced when these lines are combined.

The three-phase X-ray generator’s enhanced efficiency, which enables it to produce the intended amount of X-rays for an X-ray tube given that the peak voltage and the applied voltage during exposure are very near, is its key advantage.

High-Frequency Generator

The high-frequency generator has become the favored X-ray generator for most X-ray specialists in the industry due to its capacity to transform low-frequency and low-voltage input into a waveform with high-frequency and low-voltage.

X Ray Generator Safety Measures

Radiographic technologists must be aware of radiation safety measures in the radiology department and also for hospital management.

Hospital safety includes humans, patients, staff, and a safe environment.

The x-ray room location should be pre-planned, as we know that x-ray generators produce x-rays when an eclectic supply is provided to it, so it is the primary component of the x-ray machine unit and must be proper care taken for the x-ray generator.

To ensure the safety measures of x-ray generators, few rules and guidelines must be followed.

X-ray Generator Safety Measures Guidelines

The main precautions and guidelines that must be followed while using x ray generators are the following;

Training and Certification

The main and essential role of all personnel is to have a valid certification and training letter, that shows you have attended classes and completed your training with a certification, and this also adds value to your resume.

Radiation Protection Equipment

Radiation protection equipment including lead aprons, thyroid shielding, and lead gloves, must be entitled while performing scans.

These devices are the main barriers that minimize radiation exposure and keep human tissues from harmful radiation at the time of exposure.

Exposure time and Dose Optimization

Every radiographer must follow the ALARA Principle.

Most x-ray generators come with AEC, which adjusts x-ray beam intensity according to the patient size and image quality. These AEC optimize radiation exposure and keep radiation safety entitled.

Control Access and Radiation Signs

X ray room access is only for authorized personnel only, no patients or their guardian must not allowed in x ray control area.

The x-ray team must be aware of all radiation signs to prevent accidental exposure.

These factors also influence the safety of x-ray generators installed in the x-ray unit.

Proper use of x ray units keeps x ray generators safe and maintains x ray quality and quantum also and contributes to a safer and more efficient healthcare environment.

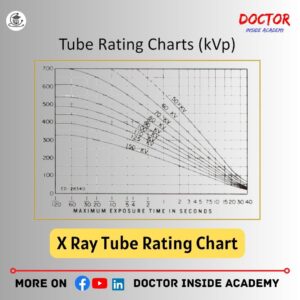

X Ray Tube Rating Chart

When the x-rays are produced, only 1% of energy is converted into useful x-ray radiation but 99% is heat, which must be controlled otherwise it may corrode the x-ray tube easily.

In this case, we use x-ray tube rating charts, which are very important in the operation of x-ray generators in medical imaging. These charts provide the required information that gives the maximum usability of x-ray tube by an authorized personnel team while ensuring safety measures and usage.

These charts help in maintaining patient safety and image quality.

What is X Ray Tube Rating Chart?

The X-ray tube rating chart is a graphical representation that displays the safe operating limits of an X-ray tube.

It specifies the maximum allowable combinations of tube current (measured in milliamperes, mA) and tube voltage (measured in kilovolts, kVp) for a given exposure time (measured in milliseconds, ms) or exposure factor.

The chart is specific to each X-ray tube model and is provided by the manufacturer.

Components of X Ray Tube Rating Chart

Here are the components of x ray tube rating chart, explained below:

kVp Range

The chart typically presents a range of kilovoltage values along the X-axis, representing the voltage applied to the X-ray tube.

This range indicates the tube’s capabilities for various radiographic examinations.

mA Range

The Y-axis displays the milliampere range, representing the tube current or the number of electrons flowing from the cathode to the anode in the X-ray tube.

Different mA values are used for different types of examinations.

Exposure Time and Exposure Factors

Some charts include additional information about the corresponding exposure times for specific mA and kVp settings. Exposure factors, which are combinations of mA, kVp, and time, are also sometimes indicated on the chart.

Importance of x ray Tube Rating Charts

The importance of x-ray tube rating charts is very crucial and those are explained below;

Safety and Tube Protection

The primary purpose of tube rating charts is to ensure the safe operation of X-ray tubes. Exceeding the maximum ratings could lead to overheating, damage, or catastrophic failure of the tube, which may endanger patients, operators, and other medical staff.

Optimizing Image Quality

Following the recommended exposure settings from the rating chart helps radiographers produce high-quality diagnostic images with appropriate contrast and resolution. Using settings within the tube’s rated limits also minimizes the chances of image artifacts.

Minimizing Patient Dose

Operating the X-ray tube at optimal settings ensures that patients receive the necessary diagnostic information while minimizing unnecessary radiation exposure.

Interpreting x ray tube rating chart

To interpret the X-ray tube rating chart correctly, radiographers need to identify the specific X-ray tube model and understand the different exposure factors associated with various imaging techniques.

Each chart might be accompanied by usage guidelines from the manufacturer to facilitate proper interpretation and application.

X-ray tube rating charts are indispensable tools for radiologic technologists and radiographers to ensure the safe and effective operation of X-ray generators.

By adhering to these charts and staying within the recommended exposure limits, healthcare professionals can optimize image quality, minimize patient radiation dose, and protect the integrity and longevity of the X-ray tube.

Understanding and respecting the significance of X-ray tube rating charts is a fundamental aspect of maintaining patient safety in medical imaging.

Few Safety Measures while Installing X Ray Unit

Few safety measures while installing x ray unit are the following;

- Electric power supply,

- Power back source,

- Proper room layout with proper lead protection and shielding,

- Floor must have a weight-bearing capacity,

- Proper ventilation and cooling services,

- Proper room light setup,

- Emergency off switches must be installed,

- Proper earthing.

While installing an x-ray tube unit, these all factors must be addressed to ensure the safety of the radiology department and hospital.

X-Ray Tube Overload Protection Circuits

X-ray tubes work by passing high-voltage electrical currents through the cathode and accelerating electrons towards the anode. The rapid deceleration of these electrons at the anode produces X-rays.

However, this process generates significant heat, which can lead to thermal stress on the X-ray tube’s components. Prolonged exposure to excessive heat or high currents can cause damage to the anode, focal spot, and other critical elements within the tube.

This damage not only reduces the X-ray tube’s lifespan but also compromises image quality and poses safety risks to both patients and medical staff.

X-ray tube overload protection circuits play a crucial role in mitigating the risk of damage caused by excessive heat or current.

These circuits are designed to monitor various parameters, such as the tube current, tube voltage, and exposure time, to ensure they stay within safe operating limits.

When any of these parameters approach or exceed predefined thresholds, the protection circuitry intervenes to prevent potential damage to the X-ray tube.

As we know x-ray tubes are very cost-effective and very useful for diagnostic purposes in healthcare.

Key Components of Overload Protection Circuits

X Ray tube overload protection includes all these aspects, which play a very important role in maintaining x ray tube circuits properly.

Current Monitoring

Overload protection circuits continuously monitor the tube current during an X-ray exposure.

If the current exceeds the safe limit due to factors like a short circuit or malfunctioning tube, the circuit triggers an automatic shutdown to prevent further current flow.

Voltage Monitoring

To avoid excessive electron acceleration and its related heat production, the protection circuit monitors the tube voltage.

If the voltage exceeds the safe range, the circuit acts promptly to stop the exposure.

Time Control

Exposure time is another critical factor that can impact the X-ray tube’s heat generation.

Overload protection circuits incorporate timers to limit the duration of X-ray exposure, preventing potential overheating.

Temperature Sensors

Some advanced protection circuits include temperature sensors placed near critical components of the X-ray tube.

These sensors constantly monitor the temperature and can activate protective measures if the temperature rises beyond acceptable levels.

Interlock Systems

Overload protection circuits are often integrated with interlock systems that connect to other safety mechanisms within the X-ray system.

In the event of an overload, the interlock system triggers an immediate shutdown, ensuring the safety of both the equipment and personnel.

Final Words

In this Chapter 4 of X Ray Course, we learned about x ray generators and their circuits with their safety measures.

I hope you enjoyed this article and get towards your academic career and you can connect with us on all social media.

Disclaimer

This article’s information is solely for educational purposes. Based on many studies, we maintain the material up to date and correct. You may use this article’s content with proper attribution, and misuse of the content is banned.

The article material is based on the author’s learning, experiences, and research, and we do not provide particular advice and suggestions at an individual level.

External links to other websites or resources may be included on this page. We have no control over the supply of concrete.

Do not take any medical advice from this site without first talking with your doctor or physicians.